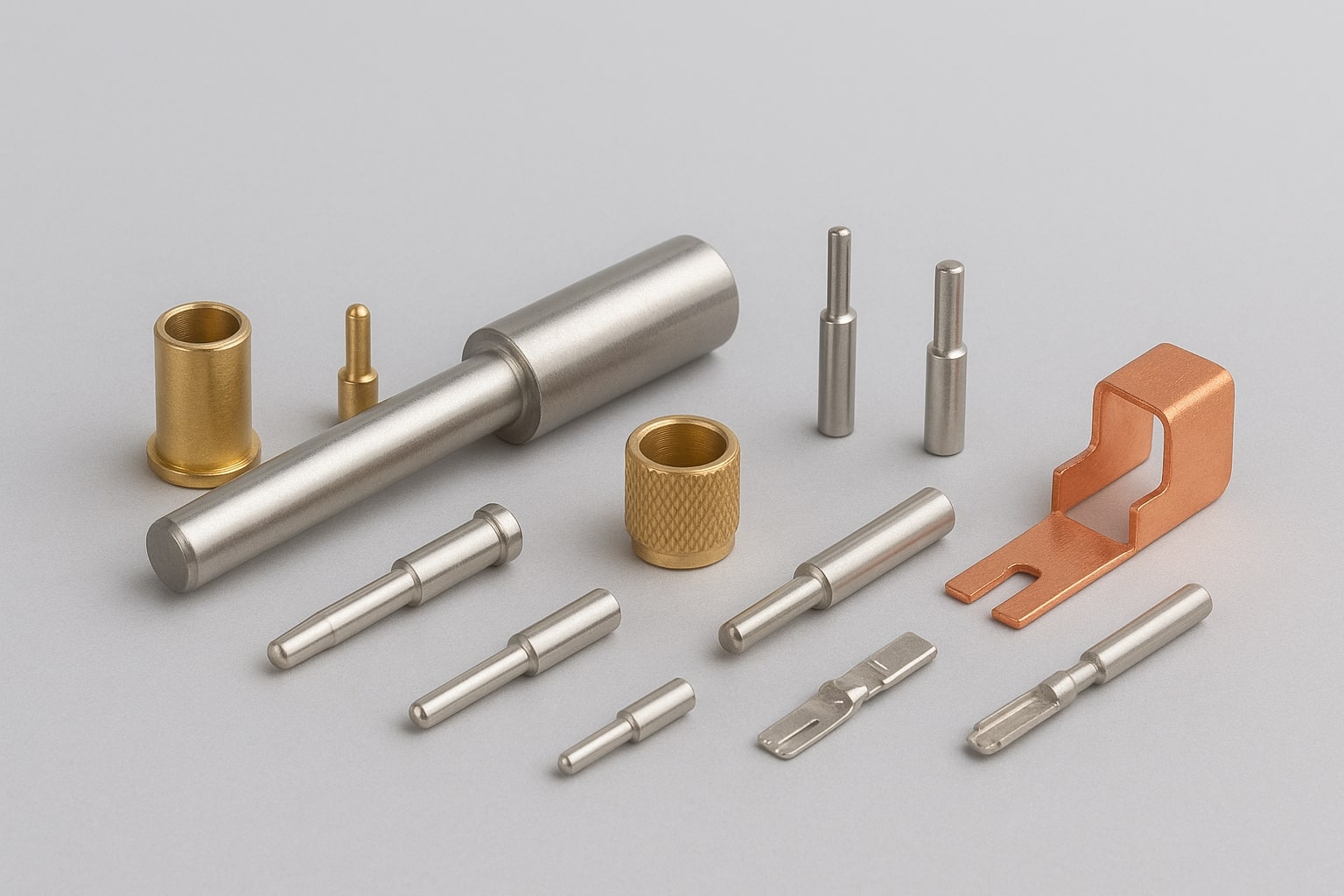

Precision Machining in Electrical Contact Pins: The Hidden Strength Behind Reliable Connections

n every electrical or electronic assembly, there’s one component that silently ensures performance — the contact pin. Whether it’s a connector in a control panel, a plug in a power supply, or a terminal block in an automation system, these tiny precision parts play a big role in maintaining conductivity, strength, and long-term reliability.

At RPM Metal Industries, we’ve seen how precision-machined electrical pins can make all the difference between a reliable connection and a system failure. Our experience in custom metal machining for the electrical industry gives us a front-row seat to the evolving needs of OEMs who demand tighter tolerances, better conductivity, and material-specific performance.

Why Precision Machining Matters

Electrical pins are more than just metal rods — they are the conductive pathways that carry current through assemblies. The accuracy of their diameter, surface finish, and concentricity directly affects how efficiently current transfers through connectors.

Through CNC machining and micro-tolerance finishing, we achieve consistent pin dimensions that fit perfectly into housings, sockets, or molded assemblies. This level of precision not only ensures smooth assembly but also minimizes resistance losses, improving the overall efficiency of electrical systems.

Materials That Define Performance

Different applications demand different materials.

We commonly manufacture electrical pins and connectors from:

-

Brass – for its balance of strength, conductivity, and corrosion resistance.

-

Copper – ideal for high-conductivity contact pins and terminals.

-

Nickel or Silver-Coated Finishes – to enhance surface conductivity and wear life.

Each material is selected based on the electrical load, operating environment, and mating component requirements, ensuring every part performs as expected in the final assembly.

Custom Machining for OEM and Electrical Industries

Unlike catalog-based suppliers, RPM Metal Industries focuses on custom-built components. Every pin, plug, or terminal we manufacture is made as per customer drawings, ensuring compatibility with proprietary electrical systems.

From slotted pins, threaded contact pins, and knurled connectors to molded and assembled screw-type contact pins, we provide solutions for applications in:

-

Power transmission and control systems

-

Automotive and EV electrical assemblies

-

Industrial connectors and sensor housings

-

Switchgear and instrumentation components

Engineering Reliability Into Every Connection

Each machined contact pin undergoes dimensional inspection and conductivity checks before dispatch. Our emphasis on surface integrity, plating quality, and burr-free finishing ensures that the final component integrates seamlessly into customer assemblies.

This attention to detail reflects our belief that quality begins at the smallest component level.

Electrical systems rely on unseen heroes — the precision-engineered metal pins and contact terminals that keep power flowing safely and efficiently. Through advanced machining, material expertise, and custom design capability, RPM Metal Industries continues to support OEMs and electrical equipment manufacturers with reliable, high-performance metal components made exactly to their needs.