The Enduring Value of Bronze and Gunmetal Components in Modern Engineering

A Metal with a Legacy of Performance

Few materials have stood the test of time in engineering as well as bronze and its close alloy, gunmetal. From ancient artistry to modern machinery, these copper-based alloys continue to prove their value in industries that demand reliability, precision, and resistance to wear and corrosion.

Today, bronze and gunmetal remain integral to industrial design — not because of tradition, but because of performance rooted in metallurgical science. They offer an ideal balance between strength, machinability, and resistance to friction, making them indispensable in modern mechanical and marine systems.

Industrial and Mechanical Applications

Bronze and gunmetal play a vital role wherever motion and load intersect.

Their self-lubricating properties reduce friction, extend component life, and maintain operational stability.

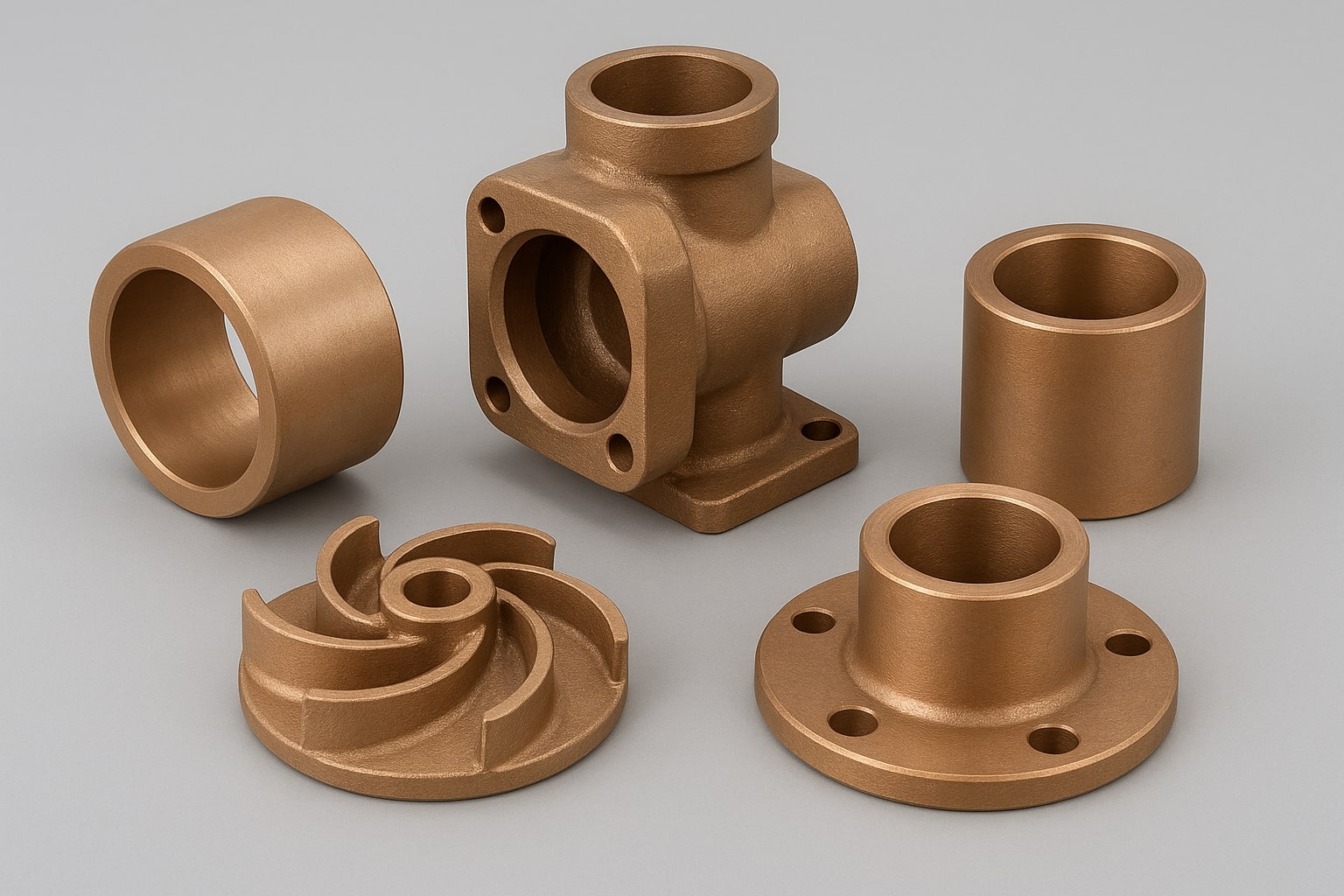

They are widely used in:

-

Bushings and bearings for engines, electric motors, and heavy machinery

-

Gears and cams, where controlled wear and smooth engagement are essential

-

Pump and valve components, providing dependable sealing and corrosion resistance

-

Hydraulic systems, where bronze cylinder heads and guide bushings endure continuous stress

For engineers, these alloys deliver reliability without compromising on precision — a balance that few materials achieve.

Marine and Offshore Engineering

Saltwater environments are among the harshest on metal. Bronze’s natural resistance to corrosion makes it a cornerstone material in marine design.

It is commonly used for propellers, shafts, and submerged bearings, where it withstands long-term exposure to seawater without degradation.

Gunmetal, a variant of bronze with tin and zinc, offers even better castability and mechanical stability, ideal for marine valves, fittings, and piping systems that demand leak-free operation and longevity.

Electrical and Power Systems

Certain bronze alloys, especially phosphor bronze, offer both conductivity and strength. This combination makes them invaluable in electrical infrastructure.

They are used in connectors, terminals, springs, and switchgear components — parts that require both precision and endurance under repetitive electrical and mechanical loads.

Unlike many other conductive materials, bronze maintains its integrity in humid or corrosive environments, making it a dependable choice for long-term installations.

Architectural and Artistic Design

Bronze’s appeal extends beyond function. Its warm tone, natural oxidation, and fine casting characteristics make it a favorite for architectural hardware, sculptures, and decorative fixtures.

In architecture, it offers both strength and beauty — from door handles and facades to heritage restorations and public art installations.

Its patina, rather than being a flaw, is a mark of authenticity — a visual reminder of endurance over time.

A Material for the Future

While advanced composites and high-strength alloys continue to evolve, bronze and gunmetal remain relevant because they strike a balance that few materials achieve: durability, machinability, and aesthetic value.

In a world seeking both performance and sustainability, these copper-based alloys are being reimagined through modern manufacturing techniques — from CNC precision machining to controlled casting for high-repeatability components.

As industries move toward longer equipment life cycles and lower maintenance costs, the role of bronze and gunmetal only becomes more essential.