Understanding Hydraulic Manifolds: The Hidden Power Behind Efficient Fluid Systems

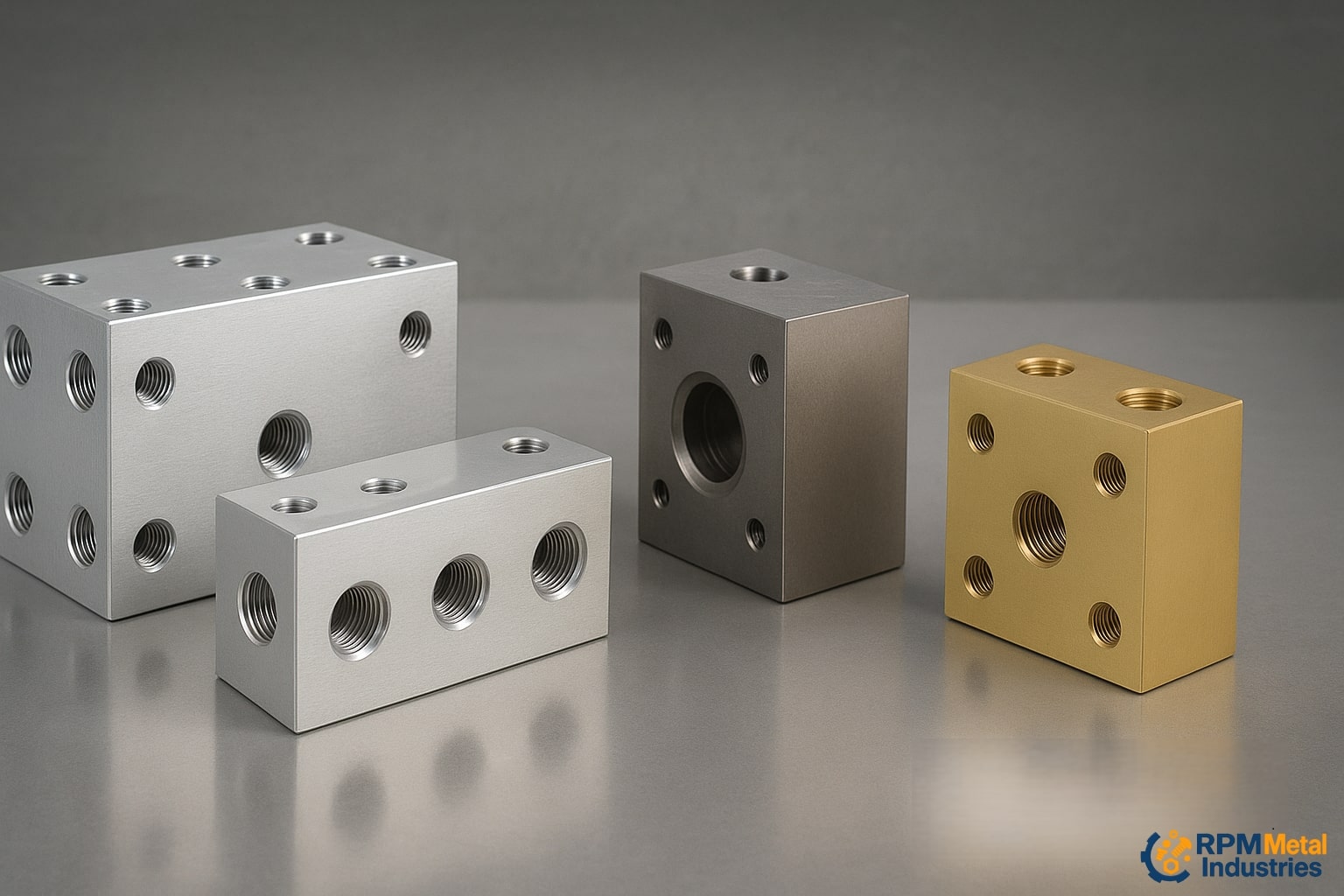

In any hydraulic or pneumatic system, the manifold plays a silent yet crucial role — guiding, controlling, and optimizing the flow of fluids between pumps, actuators, and valves. While it may look like just a block of metal, a manifold is actually a precision-engineered component that determines how smoothly and efficiently an entire system operates.

What Is a Hydraulic Manifold?

A hydraulic manifold is a solid metal block with a network of internal channels and ports. These passages direct the flow of hydraulic oil or compressed air to various points in a machine, much like how a switchboard directs electricity.

By integrating multiple valves and connections into a single compact unit, manifolds help reduce leak points, minimize hose lengths, and simplify system maintenance.

How Manifolds Are Made

The manufacturing process of a manifold involves multiple precise steps:

- Design & Simulation: Engineers create a 3D flow layout to ensure pressure balance and minimize internal turbulence.

- Material Selection: Common materials include aluminum (6061-T6) for lightweight systems, steel (EN8, C45) for high pressure, and stainless steel (SS316) for corrosive environments.

- CNC Machining: Each hole, port, and thread is drilled and milled with tight tolerances to maintain flow accuracy.

- Deburring & Cleaning: Any burrs or debris are removed to prevent contamination during operation.

- Testing: Each manifold undergoes pressure and leak testing to ensure reliability before dispatch.

At RPM Metal Industries, these processes are not just steps they are checkpoints in a controlled workflow that ensures every manifold delivers consistent, repeatable performance.

Why Manifolds Matter in Modern Engineering

Manifolds aren’t just connectors — they are system optimizers.

They help:

- Reduce space and assembly time.

- Improve safety by minimizing external piping.

- Enhance efficiency by controlling flow direction and pressure drops.

- Simplify maintenance and troubleshooting.

From hydraulic presses and mobile equipment to industrial automation and aerospace systems, manifolds form the backbone of reliable fluid power control.

The Future of Manifold Design

With advancements in CNC technology, CAD/CAM software, and 3D flow analysis, modern manifolds are becoming smarter and more compact.

Custom designs allow manufacturers like RPM Metal Industries to integrate multiple circuits, optimize internal paths, and even combine hydraulic and electronic controls in hybrid systems.